Metal Roof Parts: Best Essentials

Metal Roof Parts: Vital Tips

When discussing the longevity and durability of a home, the conversation often turns to the specific components that make up the protective layer above our heads. Understanding metal roof parts is crucial for any homeowner looking to invest in a roofing system that withstands the elements. Whether you are building a new home or renovating an old one, knowing the intricacies of these components ensures you make informed decisions. This guide explores everything from identification to installation, helping you navigate the complex world of roofing hardware.

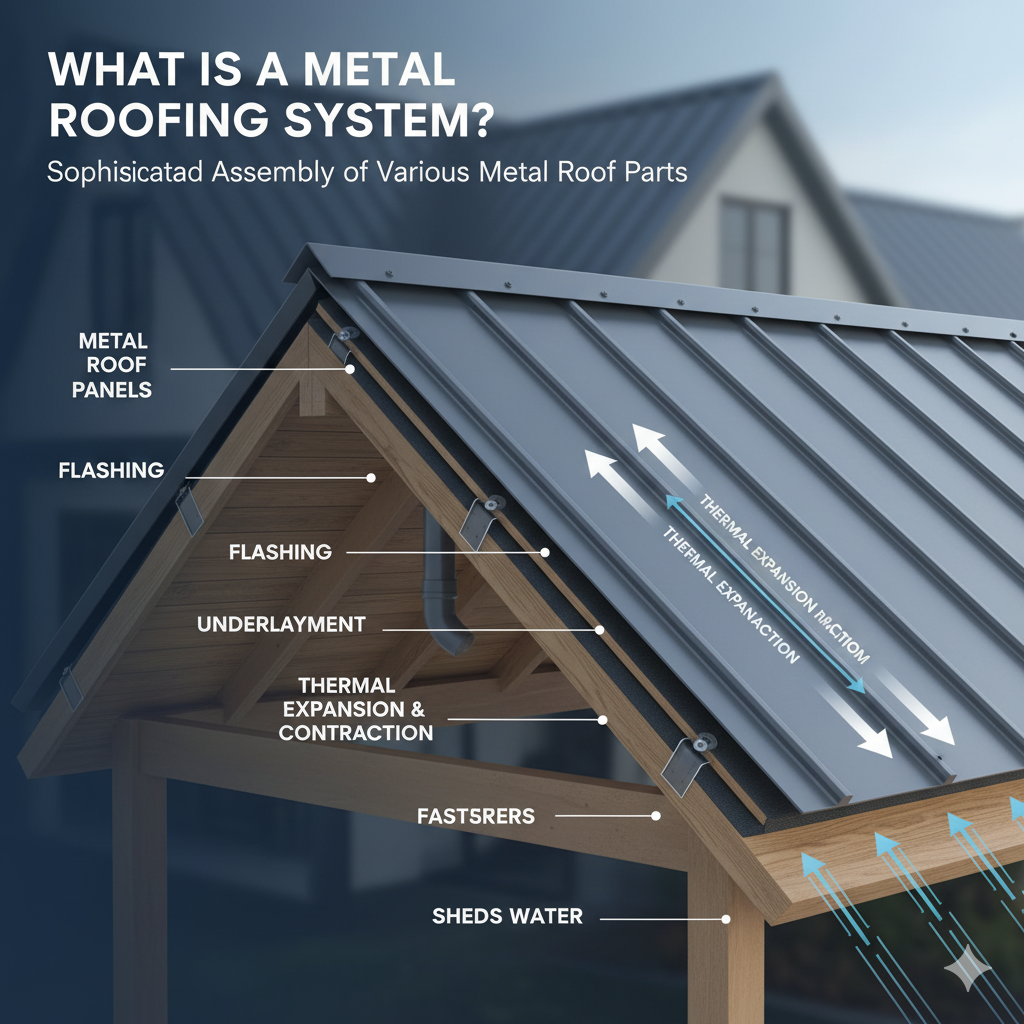

What Is a Metal Roofing System?

A metal roofing system is not just a collection of sheets nailed to a deck; it is a sophisticated assembly of various metal roof parts working in unison to shed water and protect the structure. At its core, this system involves panels, flashing, fasteners, and underlayment. The primary function is to create a watertight seal that resists wind, rain, and snow.

Unlike asphalt shingles, which rely on gravity and overlapping layers, metal systems often use interlocking mechanisms or specific fasteners to secure the material. The metal roof parts involved in this process are engineered to handle thermal expansion and contraction, which is a common occurrence with metal materials.

Furthermore, the materials used for these metal roof parts can vary significantly. You might find components made from:

-

Galvanized steel

-

Aluminum

-

Copper

-

Zinc

Each material offers different benefits regarding corrosion resistance and aesthetic appeal, but they all serve the same fundamental purpose within the assembly.

What Are the Parts of a Metal Roof Called?

To effectively manage a roofing project, you must speak the language of the trade. This special section covers four critical topics regarding identification and diagrams.

1: What Are the Parts of a Metal Roof Called

The terminology can be confusing, but the main metal roof parts have specific names. The Ridge Cap sits at the very peak of the roof where two slopes meet. Eave Trim is located at the bottom edge of the roof, directing water away from the fascia. Rake Trim covers the sloped edges of the roof. Valleys are the internal angles where two roof planes intersect, requiring specific flashing. Finally, Fasteners are the screws or clips that hold everything together.

2: All Parts Needed for a Metal Roof

A complete list of metal roof parts needed for installation includes the primary panels, drip edge, gable trim, sidewall flashing, end wall flashing, ridge caps, transition flashing, pipe boots, butyl tape, and sealant. You also need underlayment, which acts as a secondary barrier.

3: Metal Roof Parts Diagram

If you look at a diagram of metal roof parts, you will see the underlayment goes down first. The drip edge is installed at the eaves. Panels are laid out over the field of the roof. The rake trim creates a finished look on the sides, while the ridge cap seals the top.

4: Can You Replace Part of a Metal Roof

Yes, you can replace a specific section. Because metal roof parts are modular, damage to one panel or piece of flashing does not ruin the whole system. You simply unfasten the damaged component and install a new one.

How to Find Quality Components

Finding high-quality metal roof parts requires a bit of research. You cannot simply walk into a general store and expect to find professional-grade materials. The best place to start is with specialized roofing supply distributors. These vendors cater specifically to contractors and knowledgeable homeowners, ensuring that the metal roof parts they stock meet industry standards.

When searching, look for manufacturers that offer warranties. A warranty is a strong indicator that the company stands behind its metal roof parts. If a manufacturer is willing to guarantee their flashing or panels for 20 or 30 years, it suggests the material is durable.

Always check the gauge (thickness) of the metal. Lower gauge numbers mean thicker metal. For residential use, 24 or 26-gauge steel is standard for high-quality metal roof parts. Anything thinner, like 29-gauge, might be susceptible to hail damage.

How to Buy the Right Materials

Buying metal roof parts involves more than just swiping a credit card. You need a detailed materials list based on your roof’s measurements. Before you buy, ensure you have calculated the square footage of the roof, the linear footage of the ridges, eaves, and valleys, and the number of penetrations (like vent pipes).

Once you have your measurements, approach a supplier to get a quote. Ask specifically if the quote includes all necessary metal roof parts, including clips, screws, and sealants. Some suppliers might quote only the panels to make the price look lower, leaving you to buy expensive accessories later.

-

Request Samples: Ask to see samples of the metal roof parts to verify the color and finish.

-

Verify Coatings: Ensure the paint system is Kynar 500 or Hylar 5000, which resists fading.

-

Check Delivery: Metal panels are long and heavy; ensure the supplier can deliver to your site.

When you buy metal roof parts, also consider purchasing a little extra. Having spare screws or an extra piece of flashing can save you from halting the project if a mistake is made during cutting or installation.

What Is the Cost of Components?

The price of metal roof parts varies widely based on the material type and the complexity of the profile. Generally, steel is the most affordable, while copper is the most expensive.

-

Steel Panels: These typically cost between $1.00 and $3.00 per linear foot, depending on the width and gauge.

-

Aluminum: Expect to pay 20% to 30% more than steel for these metal roof parts due to their rust-proof nature.

-

Trim and Flashing: These are often sold in 10-foot sticks. A ridge cap might cost $20 to $30 per piece, while simple drip edges could be $10 to $15.

Accessories add up quickly. A box of high-quality screws (fasteners) can cost $40 to $60. Pipe boots, sealants, and butyl tape are additional costs associated with metal roof parts.

How Much Does Installation Cost?

If you are hiring a professional, the labor cost will likely exceed the cost of the metal roof parts themselves. Installing a metal roof is labor-intensive and requires specialized skills.

On average, installation costs range from $3.00 to $10.00 per square foot for labor. This price depends on the pitch of the roof, the complexity of the angles, and the type of system (exposed fastener vs. standing seam).

The installation of specific metal roof parts like flashing around chimneys or skylights takes time and precision. If a roof has many valleys or dormers, the labor cost increases because cutting and fitting these metal roof parts is slow work.

Consequently, a total project cost (materials plus labor) for a typical home usually falls between $10,000 and $25,000. While this is higher than asphalt shingles, the longevity of the metal roof parts often justifies the initial investment.

How Long Do These Components Last?

One of the main selling points of metal roof parts is their incredible lifespan. When installed correctly, a metal roof can last 40 to 70 years. This is significantly longer than the 15 to 20 years expected from traditional asphalt shingles.

The longevity depends on the material:

-

Galvanized Steel: 40–60 years

-

Aluminum: 50+ years

-

Copper/Zinc: 100+ years

However, the lifespan is not just about the metal panels. The accessories matters too. Rubber washers on screws can degrade over time due to UV exposure. These small metal roof parts may need to be replaced after 15 or 20 years to maintain the watertight seal.

How to Install the System

Installing metal roof parts is a systematic process that must be followed strictly to prevent leaks. It starts with a solid deck.

Step 1: Preparation

Remove old roofing if necessary and repair any damaged decking. Install a high-quality underlayment over the entire deck. This is a critical layer that sits beneath the metal roof parts.

Step 2: Eave Trim

Install the drip edge along the eaves. This is the first of the metal components to go down.

Step 3: Panel Layout

Begin installing panels. For vertical panels, start at one end and work your way across. Ensure the panels are square to the eave.

Step 4: Fastening

Secure the panels using the appropriate fasteners. If using an exposed fastener system, screw through the flat part of the panel (or rib, depending on manufacturer instructions) into the wood deck. Be careful not to overtighten, as this damages the washers on these metal roof parts.

Step 5: Flashing and Trim

Install gable trim along the rake edges. Install the ridge cap last to seal the peak. Use butyl tape between overlapping metal roof parts to ensure a water-tight seal.

How to Clean and Maintain

Cleaning metal roof parts is relatively simple but requires caution. Over time, dirt, algae, or leaves can accumulate, trapping moisture against the metal.

To clean, use a solution of mild laundry detergent and water. Apply it with a soft-bristle brush or a low-pressure sprayer. Never use a high-pressure washer on metal roof parts, as the force can drive water under the panels or strip the paint coating.

Cleaning out gutters is also part of maintaining metal roof parts. Clogged gutters can cause water to back up under the eave trim, leading to rot. By keeping the drainage system clear, you protect the integrity of the lower roof components.

Advantages of Metal Components

The advantages of choosing high-quality metal roof parts are numerous.

-

Durability: They withstand high winds, heavy snow, and hail better than most other materials.

-

Fire Resistance: Metal is non-combustible, providing a high fire rating.

-

Energy Efficiency: Many metal roof parts are coated with reflective paint that reduces cooling costs in the summer.

-

Aesthetics: They come in various styles and colors, mimicking slate, tile, or shakes.

Furthermore, metal roof parts are environmentally friendly. They are often made from recycled materials and are 100% recyclable at the end of their life, unlike asphalt shingles which end up in landfills.

Challenges Connected to Metal Roofing

Despite the benefits, there are challenges associated with metal roof parts.

-

Cost: The initial investment is high.

-

Noise: Rain or hail can be noisy on a metal roof, although proper insulation mitigates this.

-

Expansion/Contraction: Metal expands with heat. If metal roof parts are not installed with room to move, they can buckle or loosen fasteners.

-

Color Matching: If you need to replace a panel years later, matching the color of faded metal roof parts can be difficult.

Navigating these challenges requires careful planning and hiring experienced installers who understand how to handle these specific materials.

FAQ

What is the most important part of a metal roof?

While the panels are the most visible, the flashing is arguably the most critical among metal roof parts. Flashing seals the joints and transitions where leaks are most likely to occur. Without proper flashing, the best panels in the world cannot keep a building dry.

Can I install metal roof parts over shingles?

Yes, in many cases, you can install metal roof parts directly over existing asphalt shingles. This saves on tear-off costs and keeps waste out of landfills. However, you must use a layer of underlayment or furring strips between the old shingles and the new metal to prevent abrasion.

Do metal roof parts attract lightning?

No, metal roof parts do not increase the likelihood of a lightning strike. In fact, if lightning does strike, a metal roof is safer because it is non-combustible and can disperse the electrical charge safely into the ground if properly grounded.

How do I stop screws from backing out?

Screws backing out is caused by thermal expansion and contraction. To prevent this, ensure the metal roof parts are installed into solid wood decking and that the correct type of wood-grip screws are used. Checking fasteners every few years is good maintenance practice.

Is underlayment necessary for metal roofs?

Absolutely. Underlayment provides a secondary barrier against moisture and prevents chemical reactions between the metal roof parts and the roof deck or old shingles. It is a vital component of the total system.

Conclusion

Investing in a roofing system is a significant decision that impacts the safety, value, and appearance of your home. By understanding the various metal roof parts, from the ridge cap down to the eave trim, you empower yourself to make better choices regarding materials, installation, and maintenance. Whether you are concerned about the cost, the longevity, or the aesthetic appeal, knowing how these components work together is the key to a successful project.

A roof is more than just a cover; it is a complex system of metal roof parts engineered to protect everything you value. With proper selection and care, these components will serve you reliably for decades, offering peace of mind through every storm and season. Remember to source your materials from reputable suppliers and prioritize quality over the lowest price to ensure your home remains secure and beautiful.

🧩 Other Resources

Explore these trusted guides to better understand metal roofing components, trim pieces, and accessory systems:

-

Gulf Coast Supply – Metal Roofing Components & Trim – Educational overview of metal roof trim, panels, and finishing components.

-

Western States Metal Roofing – Accessories – Full range of metal roofing accessories including flashing, closures, and fasteners.

-

Clear Cut Exteriors – Metal Roof Anatomy – Visual breakdown explaining each part of a metal roofing system.

-

YouTube – Metal Roof Components Explained – Video guide showing how metal roof components work together.

🔎 Other Helpful Articles

-

Metal Roof Drip Edge – Why drip edge flashing is essential for metal roofs.

-

Metal Roof Underlayment – Choosing the right underlayment for performance and durability.

-

New Metal Roof Cost in Fort Walton Beach, Florida – Local pricing guide for metal roof installation.