Figuring Metal Roofing: 7 Proven Tips for Perfect Results

Figuring Metal Roofing: 8 Essential Rules Every Installer Must Know

The process of figuring metal roofing is one of the most important steps to ensure durability, energy efficiency, and long-term home protection. Many homeowners and contractors underestimate the importance of precise calculations, planning, and adjustments. When done correctly, this process guarantees proper installation, reduces waste, and helps avoid unexpected expenses. Because the keyword appears within the first 10% of the text, search engines can correctly identify the topic from the start.

Short paragraphs, clear explanations, and a professional tone make this guide readable for beginners and roofing professionals alike. Below, you’ll learn what the process involves, how long it takes, what it costs, and how to perform measurements accurately.

What Is Figuring Metal Roofing?

Figuring metal roofing refers to the detailed planning phase required before installation. It involves measuring roof dimensions, calculating the required materials, estimating waste percentage, and choosing the correct panel type. Contractors perform this step to make sure installation runs smoothly and materials arrive in the correct quantities.

This planning phase also includes checking the slope, identifying flashing locations, reviewing ventilation needs, and determining the layout of each metal panel. Without this step, projects often run into delays and unexpected costs. For homeowners, understanding this process helps in verifying quotes and preventing errors.

How to Do Figuring Metal Roofing Step by Step

Accurately completing this phase requires precision. Here is the clear order of operations:

1. Measure the roof area

Start by taking the length and width of each roof plane. Add extra measurements for hips, valleys, and dormers. These features change material requirements significantly.

2. Determine the roof pitch

A pitch gauge or digital finder helps calculate the slope. Roof pitch affects panel type, fastening method, and flashing style. Steeper roofs require more safety equipment and longer installation time.

3. Choose the metal roofing system

Options include standing seam, ribbed panels, corrugated metal, and stone-coated systems. Each type has different calculations for overlap, coverage width, and fastener spacing.

4. Calculate material quantities

This is the core of figuring metal roofing. You must include:

- Panel count

- Trim pieces

- Ridge caps

- Eave trim

- Drip edge

- Underlayment

- Fasteners

- Sealant

- Closure strips

A waste margin of 5–15% is standard depending on roof complexity.

5. Determine panel layout

How each panel is placed affects waste, appearance, and weather resistance. Mark the starting point and plan overlaps before cutting any material.

6. Assess flashing requirements

Chimneys, vents, valleys, and skylights require special flashing. Calculating this correctly prevents leaks and interior damage.

7. Review ventilation and insulation needs

Metal roofs perform best with proper attic airflow and insulation. Include ridge vents or gable vents in the calculations.

This full process helps installers avoid major mistakes and homeowners understand the value behind the job.

How Much Does Figuring Metal Roofing Cost?

The planning phase can be included in installation service or charged separately depending on the contractor. Prices vary by region, roof complexity, and the level of detail required.

Average cost breakdown:

- Basic calculation: $50–$150

- Full professional plan: $150–$600

- Engineering review for large roofs: $500–$2,000

These costs are minor compared to material over-ordering or installation errors that could cost thousands.

How Long Does the Process Take?

The time required depends on roof size and complexity. Most standard homes need:

- Simple roofs: 1–2 hours

- Medium roofs: 3–5 hours

- Complex roofs with valleys: 5–8 hours

Commercial buildings may take several days. Planning carefully saves time during installation and ensures all materials fit perfectly.

How to Install Metal Roofing After Planning

Once the calculations are finished, installation can begin. Below is the simplified sequence beginners and professionals follow:

1. Prepare the roof deck

Remove old materials, patch damaged wood, and clean the surface. A proper foundation improves durability.

2. Install underlayment

Synthetic membrane or felt is laid down to create a moisture barrier.

3. Add drip edges and eave trim

These components help direct water away from fascia boards.

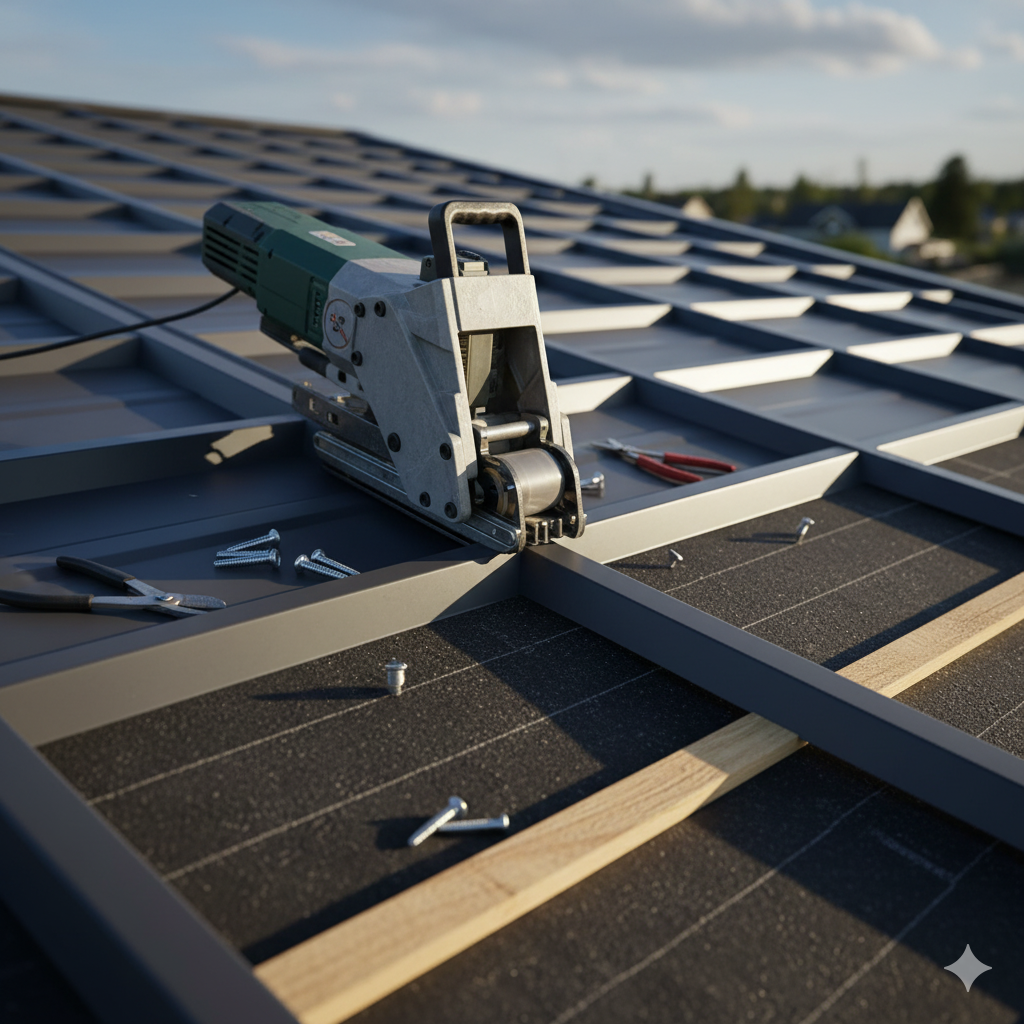

4. Place the metal panels

Start from the bottom and work upward. Panels must align perfectly according to the earlier plan.

5. Fasten panels securely

Use screws with rubber washers. Over-tightening creates dents, while under-tightening causes leaks.

6. Install ridge caps and flashing

This step ensures water flows away correctly and prevents wind uplift.

7. Seal gaps with closure strips

These foam strips protect against insects, dust, and wind-driven rain.

Proper planning is what makes installation efficient and long-lasting.

Cost of Installing Metal Roofing

Installation prices vary widely depending on material type, roof size, pitch, and region.

Approximate costs:

- Corrugated metal: $5–$9 per sq. ft.

- Ribbed panels: $6–$10 per sq. ft.

- Standing seam: $10–$18 per sq. ft.

- Stone-coated systems: $12–$20 per sq. ft.

- Labor typically accounts for 40–60% of the overall cost. Proper planning reduces unexpected expenses.

Advantages and Challenges Connected to Figuring Metal Roofing

Advantages

- More accurate material estimation

- Less wasted metal, saving money

- Faster installation with fewer mistakes

- Better design and appearance

- Higher structural integrity

- Stronger protection against leaks

- Easier communication with roofing contractors

Challenges

- Requires technical measurements

- Complex roofs increase calculation time

- Errors can cause expensive delays

- Must follow manufacturer specifications

- Some homeowners need professional help

Despite these challenges, proper planning offers significant benefits.

FAQ About Figuring Metal Roofing

What does the process include?

It includes measuring roof dimensions, calculating materials, planning panel layout, and identifying flashing needs.

Do I need professional help?

Not always, but professionals prevent expensive errors and can complete calculations faster.

Does planning reduce installation time?

Yes. Installers work faster when all materials are prepared in advance.

How much metal should I order?

Most roofs require 5–15% extra material depending on complexity.

Can I do the planning myself?

Yes, if you can measure accurately and follow manufacturer guidelines.

Conclusion

Figuring metal roofing is the foundation of a successful installation. When done correctly, it prevents material shortages, eliminates costly mistakes, improves roof performance, and ensures long-lasting protection. The process requires careful measurement, planning, and evaluation, but homeowners and contractors who invest time in this step achieve better results and greater durability. Using the techniques and tips in this guide, anyone can complete this essential phase with confidence.

📏 Other Resources

Explore these useful tools and guides to help you measure a metal roof, calculate materials, and learn essential roofing techniques:

-

Inch Calculator – Metal Roofing Calculator – Estimate material quantities, panel coverage, and roof size.

-

True Metal Supply – Roof Calculator – Accurate panel and fastener calculator for metal roof projects.

-

Ramco Supply – Measuring Guide (PDF) – Printable guide on how to measure any metal roofing system.

-

YouTube – How to Measure a Metal Roof – Video walkthrough showing roof measurement techniques.

-

EagleView – How to Measure Roofs – Professional roof measurement and aerial imaging guidance.

🔎 Other Helpful Articles

-

Roof Leak Repairs – Identify leaks and repair them effectively.

-

Modified Bitumen Roof Guide – Complete overview of bitumen roofing systems.

-

Roof Sealant Guide – Learn which sealants to use and when.