Metal Roof Underlayment: 10 Top Ways to Protect

Metal Roof Underlayment: Safe & Best Options

What Is Metal Roof Underlayment?

When homeowners consider upgrading their homes, the roof is often the first line of defense against the elements. Specifically, metal roof underlayment serves as the critical barrier installed directly onto the roof deck before the metal panels are laid down. This material acts as a secondary layer of protection, shielding the structure from moisture, ice dams, and severe weather. Without this layer, condensation that naturally forms beneath metal panels could rot the wooden decking over time.

Most people assume the metal panels do all the work, but the metal roof underlayment is the unsung hero of the roofing system. It provides a flat, even surface for the metal to rest on, reducing the noise caused by rain or hail. Furthermore, it offers temporary protection during the installation phase if the project takes several days to complete. Understanding exactly what this component does is the first step in ensuring a long-lasting roof.

There are three primary types of materials used for metal roof underlayment. The first is asphalt-saturated felt, a traditional and affordable option. The second is synthetic underlayment, which is lighter, stronger, and more resistant to tearing. The third is peel-and-stick membrane, often used in valleys and eaves for maximum waterproofing. Choosing the right one depends on your climate, budget, and the specific design of your roof.

How To Find the Right Metal Roof Underlayment

Finding the correct metal roof underlayment requires a bit of research and an understanding of your local environment. Start by consulting with local roofing suppliers who specialize in metal systems. They often carry brands that are specifically tested for the temperature fluctuations common in your area. Big-box hardware stores may have generic options, but specialized suppliers will have high-performance synthetic materials that professional roofers prefer.

Another excellent way to find quality metal roof underlayment is by reading manufacturer specifications for the metal panels you intend to buy. Many metal roof manufacturers will void their warranty if you do not use a specific type of underlayment. For example, some metal systems require a high-temperature underlayment because metal gets significantly hotter than asphalt shingles.

Checking online forums and reviews from professional roofers can also guide your search. Look for discussions regarding durability during installation, as you want a material that won’t tear under foot traffic.

Finally, consider requesting samples. Touching the material allows you to assess the thickness and texture. A good metal roof underlayment should feel robust and have a slip-resistant surface, which makes the installation process much safer for you or your contractor.

How To Buy Metal Roof Underlayment

Once you have identified the type you need, the process of buying metal roof underlayment involves calculating coverage and comparing prices. Always measure your roof’s square footage accurately, and then add at least 10% to 15% for overlap and waste. Most underlayment is sold in rolls, and the packaging will clearly state how many square feet one roll covers.

When you go to buy metal roof underlayment, check the perm rating. This rating measures breathability. In some climates, you need a breathable underlayment to let moisture escape from the attic, while in others, a vapor barrier is preferred. Ensure the product you select matches the ventilation strategy of your home.

-

Check the Warranty: Ensure the underlayment warranty matches or exceeds the lifespan of the metal roof.

-

Verify Compatibility: Confirm the material won’t react chemically with the metal panels.

-

Look for UV Resistance: If the underlayment will be exposed for weeks before the metal is installed, UV resistance is crucial.

Don’t just buy the cheapest option. Investing in a premium metal roof underlayment can save you thousands in water damage repairs down the road. It is a relatively small portion of the total roof cost, yet it performs a vital function.

What Underlayment for Metal Roof

When asking what underlayment for metal roof projects is best, the answer often points toward synthetic materials. Unlike traditional felt, synthetic options are woven from polypropylene or polyethylene, offering superior strength. They do not absorb water, meaning they won’t wrinkle and distort the metal panels above them. This is critical for aesthetic appeal and functional drainage.

Does Metal Roofing Need Underlayment

Many homeowners ask: does metal roofing need underlayment? The answer is an absolute yes. Metal creates condensation when warm air from the attic meets the cold metal surface. Without a barrier, this moisture drips onto the wood deck. Furthermore, the underlayment provides a cushion that prevents the metal from rubbing against the wood, which can degrade the panels over decades of thermal expansion and contraction.

Steel Roof Underlayment

Specific steel roof underlayment requirements often focus on high-temperature resistance. Steel can conduct immense heat, potentially melting standard asphalt-based underlayments. Therefore, a high-temp self-adhering membrane is often recommended for steel applications, particularly in hot climates.

Underlayment for Metal Roof

Ultimately, selecting the right underlayment for metal roof installations ensures the longevity of the entire system. Whether you choose a synthetic sheet or a rubberized asphalt membrane, the goal is to create a waterproof seal that acts as a second skin for your home.

How To Install Metal Roof Underlayment

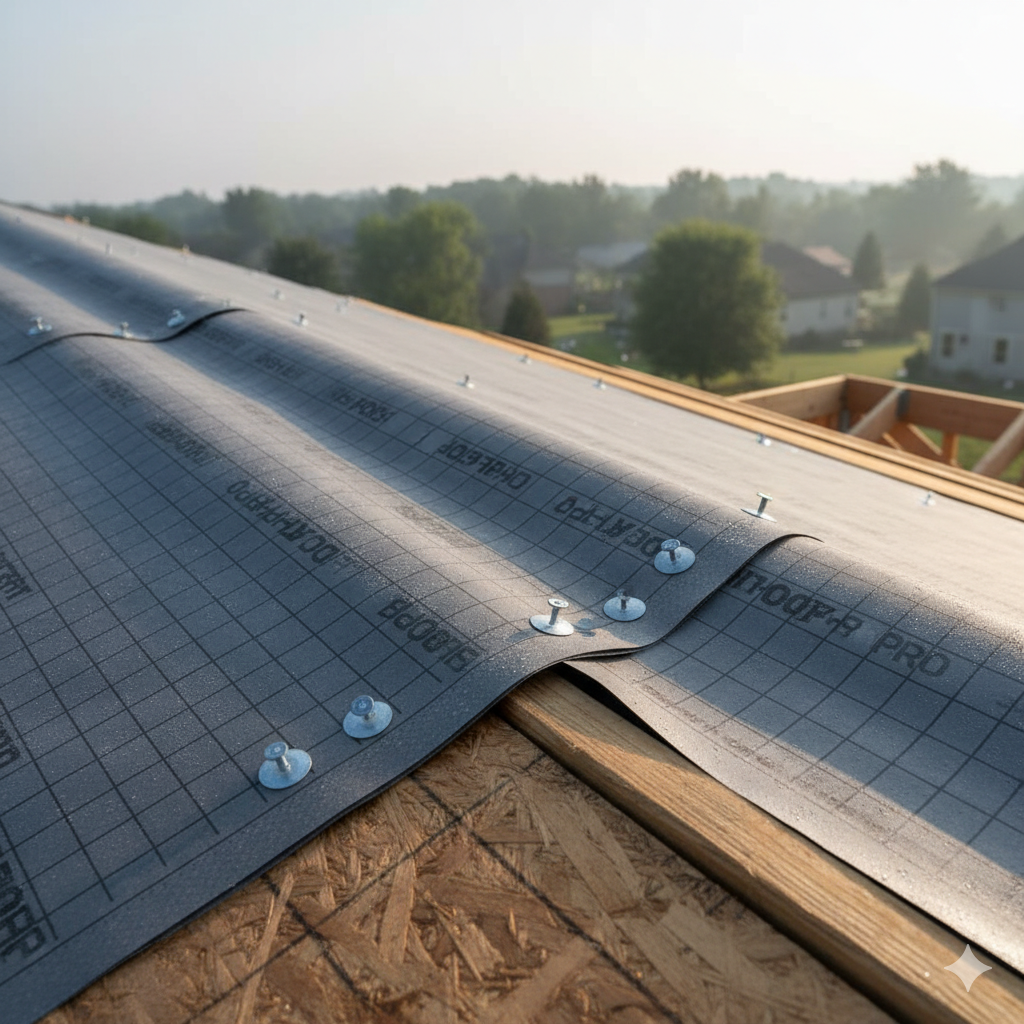

Installing metal roof underlayment is a precise process that must be done correctly to ensure warranty compliance and weatherproofing. The installation generally begins at the eaves (the bottom edge of the roof) and works its way up to the ridge. This shingle-style overlapping ensures that water flows over the laps rather than getting underneath them.

-

Clean the Deck: Ensure the roof deck is free of old nails, debris, and rot.

-

Apply Drip Edge: Install the metal drip edge along the eaves before laying the underlayment.

-

Roll Out Material: Roll the metal roof underlayment horizontally, starting at the bottom corner.

-

Fasten Properly: Use plastic cap nails rather than standard staples to prevent moisture intrusion and tearing.

-

Overlap Seams: Overlap horizontal seams by at least 4 to 6 inches and vertical seams by 6 to 12 inches.

For valleys and vulnerable areas, it is standard practice to use a self-adhering peel-and-stick metal roof underlayment. This provides an extra seal where water tends to collect. Be careful not to stretch the material too tight, but also avoid leaving wrinkles. A smooth surface is essential for the metal panels to lay flat.

Safety is paramount. Synthetic metal roof underlayment can be slippery when wet or dusty. Always wear soft-soled shoes and use safety harnesses when working on a roof. If you are unsure about the steepness or complexity of your roof, hiring a professional is the safest route.

How Much Is Metal Roof Underlayment?

The cost of metal roof underlayment varies significantly based on the material quality and brand. Generally, standard asphalt-saturated felt is the most economical choice, costing between $0.15 and $0.25 per square foot. However, it offers the least protection and durability.

Synthetic metal roof underlayment is the mid-range and most popular option. Prices typically range from $0.25 to $0.50 per square foot. While more expensive than felt, the rolls are wider and lighter, which can reduce labor costs during installation. The longevity and warranty of synthetic options usually justify the price difference.

Premium peel-and-stick metal roof underlayment is the most expensive, often costing between $0.60 and $0.90 per square foot or more. While it represents a higher upfront investment, it offers the best waterproofing capabilities, especially for low-slope roofs or regions with heavy snow and ice.

-

Budget Option: #30 Asphalt Felt ($15 – $25 per roll)

-

Standard Option: Synthetic Woven ($50 – $100 per roll)

-

Premium Option: High-Temp Peel & Stick ($150 – $200 per roll)

When budgeting for your project, remember that the metal roof underlayment is a small fraction of the total roof cost but protects the entire investment. Cutting corners here is rarely worth the savings.

How Long Does Metal Roof Underlayment Last?

The lifespan of your metal roof underlayment should ideally match the lifespan of the metal roof itself. Metal roofs are famous for lasting 40 to 70 years, so using an underlayment that degrades after 15 years is counterproductive.

Standard asphalt felt metal roof underlayment tends to dry out and become brittle over time, typically lasting 15 to 20 years. Once it cracks, it loses its waterproofing ability. This is why felt is rarely recommended for high-quality metal roofing systems that are intended to be permanent solutions.

Synthetic metal roof underlayment is designed to last much longer, often carrying warranties of 25 to 50 years. Because it is made of plastic polymers, it does not rot or degrade easily under thermal shock. High-quality synthetic options are chemically stable and can survive the high heat generated under metal panels.

Peel-and-stick membranes also offer excellent longevity, often rated for 40+ years. However, proper ventilation is key. If the attic is poorly ventilated, excessive heat can shorten the life of even the best metal roof underlayment. Regular inspections of the roof system can help ensure everything is aging as expected.

How To Clean Metal Roof Underlayment

In most cases, you will not need to clean the metal roof underlayment because it is covered by metal panels. However, during the installation phase, or if a repair requires exposing the underlayment, keeping it clean is vital for adhesion and safety.

If the metal roof underlayment is exposed to dirt, sawdust, or debris before the metal is installed, sweep it gently with a soft-bristle broom. Avoid using high-pressure washers, as this can force water under the overlaps and compromise the waterproof seal.

If you are using a peel-and-stick metal roof underlayment, the surface must be absolutely clean and dry before you adhere the next layer or the metal panels. Dust can prevent the adhesive from bonding properly to the deck or the overlap.

-

Remove large debris by hand.

-

Sweep fine dust carefully.

-

Ensure the surface is dry before proceeding.

Once the metal panels are installed, the metal roof underlayment is sealed away from dirt. The focus then shifts to cleaning the metal panels themselves to prevent algae or moss growth, which ultimately protects the underlayment beneath by ensuring proper water runoff.

What Is the Cost of Labor for Installation?

The labor cost to install metal roof underlayment is usually included in the overall quote for a roof replacement. However, if you are looking at it as a separate line item or a DIY calculation, it helps to understand the time involved.

Professional roofers can install synthetic metal roof underlayment very quickly because the rolls are wide (often 4 feet) and lightweight. Labor costs generally range from $0.50 to $1.00 per square foot for the underlayment installation portion alone. This price can increase if the roof has a steep pitch or complex valleys that require meticulous cutting and sealing.

Peel-and-stick metal roof underlayment takes longer to install because the release backing must be carefully removed to prevent wrinkles. It requires more precision, which can drive labor costs slightly higher. However, the self-sealing nature means fewer fasteners are needed, which speeds up some aspects of the job.

If you are doing it yourself to save money, the “cost” is your time and physical exertion. Installing metal roof underlayment on a 2,000 square foot roof might take a crew of two people a full day, assuming simple roof geometry. Always factor in the cost of safety gear and potential waste when calculating the true price.

Advantages and Challenges of Metal Roof Underlayment

Using the correct metal roof underlayment brings massive advantages. The primary benefit is waterproofing. It acts as a fail-safe if wind-driven rain gets past the metal panels. Secondly, it provides a thermal break. This is crucial for energy efficiency and for preventing the “sweating” of metal panels that can rot out the structure below.

Another major advantage is noise reduction. A high-quality metal roof underlayment buffers the sound of rain hitting the metal, making the interior of the home quieter and more comfortable. Without it, a metal roof can sound like a drum during a storm.

However, there are challenges. The main challenge with metal roof underlayment is choosing the wrong type. Using a low-temp underlayment under a hot metal roof can cause the material to melt and stick to the metal, potentially ruining the aesthetic and the function.

Another challenge is installation safety. Synthetic metal roof underlayment can be incredibly slippery compared to old-school felt. Roofers must take extra precautions. Additionally, leaving the underlayment exposed to UV rays for too long can degrade it before the metal is even installed. You must manage the project timeline carefully to protect the material.

FAQ

Why can’t I just put metal directly on wood?

Placing metal directly on wood is risky because condensation will form on the underside of the metal. Without metal roof underlayment, this moisture soaks into the wood, causing rot and mold. The underlayment also prevents the wood resin from damaging the metal finish.

Is thicker underlayment always better?

Not necessarily. While thickness can indicate durability, the material composition matters more. A thinner synthetic metal roof underlayment is often stronger and more effective than a thick, heavy layer of organic felt. Look for tear strength and heat resistance specs rather than just thickness.

Can I reuse old underlayment?

No, you should never reuse old material. When replacing a roof, always tear off the old layers to inspect the deck. Installing new metal roof underlayment ensures that your new roof has a fresh, warranted layer of protection that will last as long as the metal.

Does peel and stick go on the whole roof?

It depends on your climate and budget. In snowy regions, it is common to put peel-and-stick metal roof underlayment on the entire roof to prevent ice dams. In milder climates, it is often used only at the eaves, valleys, and penetrations, with synthetic mechanically attached underlayment on the rest.

How many layers do I need?

Typically, one layer of high-quality metal roof underlayment is sufficient. However, for low-slope roofs (between 2:12 and 4:12 pitch), building codes often require two layers of underlayment or a single layer of self-adhering membrane to ensure adequate water shedding.

Conclusion

In the world of home improvement, the details often matter more than the visible finish. While the metal panels provide the curb appeal and the primary shield, the metal roof underlayment provides the peace of mind. It is the essential barrier that handles condensation, prevents leaks from ice dams, and buffers sound.

Choosing the right metal roof underlayment involves balancing cost, climate requirements, and material compatibility. Whether you opt for a modern synthetic weave or a robust self-adhering membrane, ensure it is rated for high temperatures and has a lifespan that complements your metal roofing.

By understanding how to buy, install, and maintain this critical component, you ensure that your investment is secure. Don’t overlook the importance of metal roof underlayment; it is the silent guardian of your home’s structural integrity. Prioritize quality materials and correct installation techniques, and your roof will protect you for decades to come.

🏗️ Other Resources

Explore these trusted sources to learn more about underlayment for metal roofing, installation requirements, and material options:

-

Owens Corning – Metal Roof Underlayment Guide – Explains types of underlayment and why they matter for metal roofs.

-

Home Depot – Metal Roof Underlayments – Various synthetic and high-temp underlayment options.

-

Skywalker Roofing – Choosing the Right Underlayment – Professional advice on selecting the best underlayment for your project.

-

SC Metals – High-Temperature Underlayment – Specialized underlayments designed for metal roofs in hot climates.

🔎 Other Helpful Articles

-

Can You Paint a Metal Roof? – Full guide to prepping and painting metal roofing.

-

Stone-Coated Metal Roofing – Benefits and installation details of stone-coated steel systems.

-

Metal Roof Drip Edge – Why drip edges matter and how to install them correctly.