Roof Jacks for Metal Roofs: 1 Best Easy Install

Roof Jacks for Metal Roofs: Vital Safety Tips

What Are Roof Jacks for Metal Roofs?

When undertaking any roofing project, safety remains the paramount concern for both professional contractors and DIY enthusiasts. This is where roof jacks for metal roofs come into play as an essential component of a secure setup. Essentially, these devices are specialized brackets or platforms designed to create a stable foothold on the often slippery and steep surface of a metal roof. Unlike asphalt shingles, metal surfaces offer very little friction, making it nearly impossible to walk or work safely without proper equipment.

These tools function by providing a horizontal surface where you can place wooden planks, creating a staging area for materials or a walkway for the roofer. The specific design of roof jacks for metal roofs differs significantly from those used on shingled roofs. They must account for the unique profile of metal panels, such as standing seams or corrugated ridges, without damaging the finish or compromising the watertight integrity of the structure.

Understanding the mechanics of these tools is the first step toward a successful project. They usually consist of heavy-duty steel or aluminum bodies that clamp onto the standing seams or fasten directly into the decking, depending on the model. The primary goal is to distribute weight evenly and prevent the worker from sliding off the edge. Without reliable roof jacks for metal roofs, simple maintenance tasks can turn into dangerous endeavors.

Furthermore, these jacks are not just about safety; they are about efficiency. having a flat surface to place tools, drills, and screws means less time climbing up and down ladders. It stabilizes your workflow, allowing you to focus on the quality of the repair or installation rather than worrying about your footing.

How to Find the Right Equipment

Finding high-quality roof jacks for metal roofs requires a bit of research and understanding of your specific roof type. Not all jacks are universal. The first place to look is specialized roofing supply stores. These establishments often carry professional-grade equipment that you might not find at a standard big-box hardware store. They can offer advice on which jacks mate perfectly with your specific seam profile, ensuring you don’t void your roof’s warranty.

Online marketplaces are another vast resource. When searching online, be sure to read user reviews specifically from people who have used the roof jacks for metal roofs on a similar pitch and material to yours. Look for detailed specifications regarding weight limits and adjustability. You need to know if the jack can handle the angle of your slope.

Pro Tip: Always verify the “seam compatibility” when shopping online. A jack designed for a snap-lock seam might not work on a mechanical lock seam.

Another excellent way to find reliable equipment is by consulting with local metal roofing manufacturers. They often have preferred vendors or specific models of roof jacks for metal roofs that they recommend for their panels. This ensures that the clamping mechanisms won’t crimp or scratch the paint finish, which is a common concern with generic models.

Finally, consider rental options if this is a one-time project. Many equipment rental agencies stock roof jacks for metal roofs because they are durable items that are not needed permanently by homeowners. This can be a cost-effective way to get high-end, safety-compliant gear without the full purchase price.

How to Buy the Best Models

Buying the correct roof jacks for metal roofs involves more than just picking the cheapest option. You must prioritize build quality and material compatibility. Start by checking the material of the jack itself. It should be made of non-corrosive materials or heavy-gauge steel with a powder coat to prevent rust, which could stain your roof.

-

Check the Load Rating: Ensure the roof jacks for metal roofs are rated for the weight of the worker plus the weight of the plank and any materials stacked on it.

-

Inspect the Clamping Mechanism: For standing seam roofs, the clamp must hold tight without piercing the metal.

-

Look for Adjustability: The best models allow you to adjust the angle of the platform to match the pitch of the roof perfectly.

When you are ready to purchase roof jacks for metal roofs, double-check the return policy. Sometimes, a jack looks like it will fit based on the description, but once you get it up to the roof, the fitment on the seam might be slightly off. having the option to exchange it is crucial.

Don’t forget to buy the staging planks. While you are focusing on the roof jacks for metal roofs, remember that they are useless without the lumber that goes between them. Ensure you buy construction-grade lumber that is free of large knots or cracks.

Price comparison is also a key step. While you shouldn’t skimp on safety, prices for roof jacks for metal roofs can vary wildly between suppliers. Look for bundle deals if you need to buy multiple brackets to set up a long walkway.

Understanding the Variations and Costs

In the world of metal roofing safety, terminology and pricing can vary. It is important to understand specific niche terms to get exactly what you need.

Roof Jacks for Corrugated Metal Roofs

Standard clamps often fail on corrugated profiles because there isn’t a straight seam to grab. Roof jacks for metal roofs designed for corrugated styles usually require a different approach, often mounting directly into the structural purlins. This ensures stability on the wavy surface. If you have this roof type, standard seam clamps will not work, and attempting to use them is dangerous.

Pipe Jack for Metal Roof

While we are discussing safety jacks, do not confuse them with a pipe jack. A pipe jack is a flashing boot used to seal around plumbing vents. However, when searching for “jacks,” this often comes up. Ensure you are buying staging brackets, not flashing boots, although you might need a pipe jack to seal penetrations while you are up there on your roof jacks for metal roofs.

Metal Roof Jack

This is simply a shortened term for the safety bracket. A high-quality metal roof jack will feature padded clamps to protect the paint finish. Preserving the aesthetic of the roof is just as important as the structural integrity.

Metal Roof Jack Cost

The price is a major factor. A basic metal roof jack cost can range from $80 to $150 per bracket for professional standing seam models. This might seem steep, but remember, you usually need at least two, and ideally more for a full setup. Cheaper, screw-down versions exist but leave holes in the roof. Investing in non-penetrating roof jacks for metal roofs saves money on repairs later.

How Much Do They Cost?

Determining the exact cost of setting up a system using roof jacks for metal roofs depends on the scope of your project. As mentioned, individual brackets can range significantly. For a standard residential job, you might need a setup of three to four jacks to create a stable 16-foot walkway. This pushes the initial investment into the $300 to $600 range just for the brackets.

However, the cost of roof jacks for metal roofs must be weighed against the cost of an accident. A fall from a metal roof can result in medical bills that far exceed the price of safety equipment. Additionally, there is the cost of efficiency. Working without stable footing takes twice as long.

If you are a contractor, the cost is a business expense that pays for itself in one or two jobs. High-quality roof jacks for metal roofs last for years. If you are a homeowner, you can often resell the jacks after your project is complete, recouping up to 70% of the initial cost, as the market for used safety gear is robust.

Do not forget to factor in the cost of the walk-boards. While wood is generally cheap, you need top-grade lumber. Do not use old, rotted wood on your brand-new roof jacks for metal roofs. The plank is the bridge that holds you; if it snaps, the quality of the jack doesn’t matter.

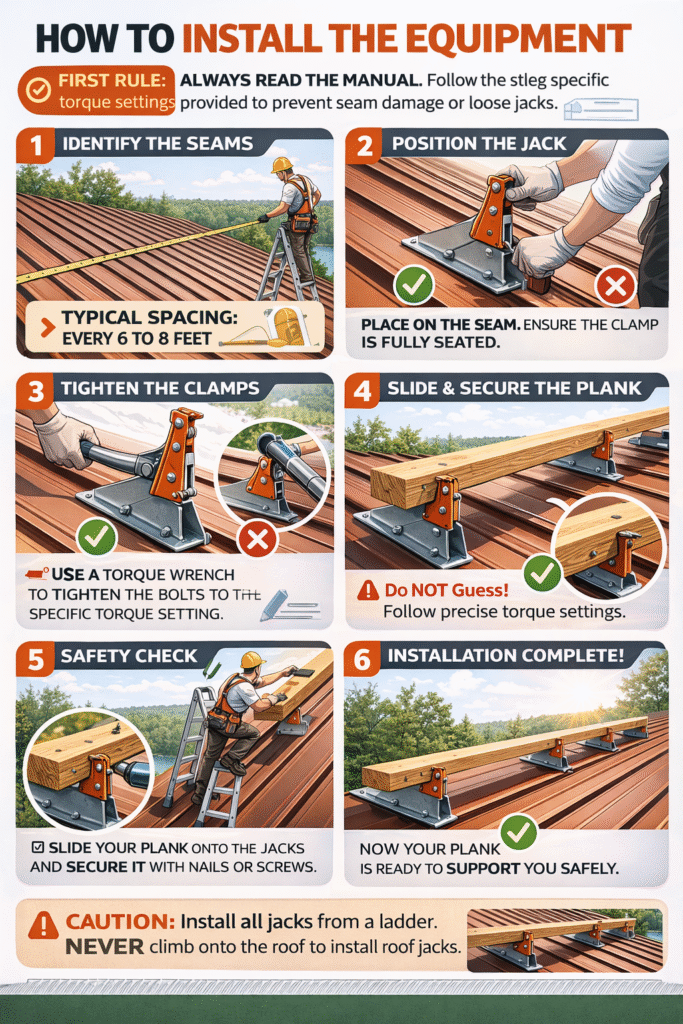

How to Install the Equipment

Installing roof jacks for metal roofs is a precise process that must be followed strictly to ensure safety. The first rule is to read the manufacturer’s manual. Every brand has specific torque settings for the bolts that clamp onto the seams.

-

Identify the Seams: Locate the standing seams where you will attach the jacks. They should be spaced appropriately for the length of your plank, usually every 6 to 8 feet.

-

Position the Jack: Place the roof jacks for metal roofs onto the seam. Ensure the clamp is seated fully against the metal fold.

-

Tighten the Clamps: Use a torque wrench to tighten the bolts. Do not guess the tightness. Over-tightening can crush the seam; under-tightening can cause the jack to slip.

Once the brackets are secured, slide your wooden plank onto the horizontal arms of the roof jacks for metal roofs. Secure the plank to the jack using nails or screws if the jack has pre-drilled holes for this purpose. This prevents the board from sliding left or right while you walk on it.

Safety Check: Before stepping onto the plank with your full weight, test the stability of the roof jacks for metal roofs by applying pressure from a ladder. Shake the setup vigorously to ensure nothing moves.

Always install the jacks from a ladder or a lower secure point. Never climb onto the roof to install the safety equipment that is supposed to protect you while you are on the roof. The installation of roof jacks for metal roofs is the first step, not the second.

How to Clean and Maintain

Maintenance of your roof jacks for metal roofs is critical for their longevity and your safety. After every job, these tools should be inspected and cleaned. Metal roofs often accumulate pollen, dust, and sometimes algae, which can transfer onto the jacks.

Clean the clamping faces of the roof jacks for metal roofs with a mild detergent and a wire brush if there is any buildup of debris. You want the metal-to-metal contact to be pure to ensure maximum friction grip. If the jacks have rubber pads to protect the roof surface, inspect these pads for cracks or wear. A worn pad on your roof jacks for metal roofs can lead to slippage or damage to the roof panels.

Lubricate the adjustable bolts and hinges. These parts can seize up if they are exposed to rain and then stored improperly. A simple spray of penetrating oil keeps your roof jacks for metal roofs ready for the next season. Store them in a dry place. Rust is the enemy of structural integrity.

If you notice any bent components or stress fractures in the metal body of the jack, discard it immediately. Do not attempt to weld or repair a damaged safety device. The structural integrity of roof jacks for metal roofs is calculated precisely; tampering with it creates a weak point.

Advantages of Using These Tools

The primary advantage of using roof jacks for metal roofs is, naturally, fall prevention. Metal roofs are notoriously slick, especially in the morning dew or after a light rain. Having a level platform changes the environment from a high-wire act to a stable construction site.

Another advantage is the protection of the roof itself. Walking directly on metal panels can lead to oil canning (denting) or scratching of the finish. By using roof jacks for metal roofs and walk-boards, you distribute your weight across the structure rather than concentrating it on your heels. This preserves the aesthetic and functional quality of the metal.

Efficiency is a massive benefit. When you have a place to set a bucket of screws or a drill, you are not fumbling with tool belts while trying to balance. Roof jacks for metal roofs allow for two-handed work, which ensures better craftsmanship. You can drive screws straighter and apply sealant more accurately.

They also allow for access to difficult areas. On very steep pitches, it is impossible to stand without them. Roof jacks for metal roofs make the “unwalkable” roofs accessible for painting, repair, or chimney maintenance.

Challenges Connected to the Equipment

Despite their benefits, there are challenges associated with roof jacks for metal roofs. The most significant is compatibility. There are dozens of metal roof profiles—standing seam, corrugated, snap-lock, butterfly seam, etc. A jack designed for one will rarely fit another. This means a contractor might need to own several sets of roof jacks for metal roofs.

Installation time is another challenge. It takes time to properly measure, torque, and set up the scaffolding. For a quick 10-minute repair, the hour-long setup of roof jacks for metal roofs can feel tedious. However, it is a necessary time investment.

Weight is also a factor. hauling heavy steel jacks and long wooden planks up a ladder is physically demanding. It requires strength and care to not drop the equipment on the roof or on oneself. The physical exertion required to set up roof jacks for metal roofs is significant.

Cost is the final barrier. High-quality, non-penetrating jacks are expensive. For a homeowner doing a one-time repair, the cost of the roof jacks for metal roofs might exceed the cost of the materials for the repair itself.

Strategies for Difficult Roof Angles

Working on extreme pitches requires specific strategies when using roof jacks for metal roofs. For low-slope roofs, you might get away with a single row of jacks. However, for steep roofs (anything over a 6/12 pitch), you will need a multi-tiered setup.

This involves installing a row of roof jacks for metal roofs near the eaves, and then another row higher up. This allows you to transfer materials up the roof in stages. It acts like a ladder system built into the roof surface.

Strategic Setup: When dealing with steep angles, always tether your tools. Even with roof jacks for metal roofs, a dropped drill becomes a dangerous projectile.

Ensure that the angle of the jack arm is adjustable. On a steep roof, a fixed 90-degree jack might angle the plank downward, making it feel like a slide. You need roof jacks for metal roofs that can be leveled perfectly horizontal regardless of the roof’s angle.

Never work alone on steep pitches, even with jacks. If you slip onto the plank and are injured, you need someone to help you down. Roof jacks for metal roofs provide a platform, but they do not replace the need for a harness and rope system on steep inclines.

FAQs About Metal Roofing Safety

Can I use wood shingles jacks on a metal roof?

No, absolutely not. Roof jacks for metal roofs are engineered specifically to clamp onto seams or mount to purlins. Wood jacks usually rely on nails driven into the deck, which would destroy a metal roof.

Do roof jacks damage the paint on the metal?

If you buy high-quality roof jacks for metal roofs, they will have rubber gaskets or blunt clamping faces designed to protect the paint. Cheap models or improper installation can cause scratches.

How far apart should I space the jacks?

Generally, you should space roof jacks for metal roofs no more than 8 feet apart. However, 6 feet is safer and provides a more rigid walkway that doesn’t bounce when you walk.

Can I rent them instead of buying?

Yes, many tool rental shops carry roof jacks for metal roofs. Just ensure they are the specific type that fits your standing seam profile.

Are they heavy to carry up the ladder?

Yes, they are solid steel or heavy aluminum. Use a rope and bucket system or a helper to hoist the roof jacks for metal roofs up to you rather than carrying them while climbing.

Do I still need a harness?

Yes. Roof jacks for metal roofs are a work platform, not a fall arrest system. OSHA regulations often require a personal fall arrest system (harness and rope) in addition to the jacks.

Conclusion

Navigating the complexities of metal roofing requires respect for the environment and the right tools. Roof jacks for metal roofs are not optional accessories; they are fundamental safety devices that separate a professional, secure job from a dangerous gamble. Whether you are dealing with a standard standing seam or a corrugated profile, there is a jack designed to keep you safe.

From understanding how to buy the correct model to mastering the installation and maintenance, every step matters. The investment in quality roof jacks for metal roofs pays dividends in safety, efficiency, and the protection of your property. Do not let the cost or the setup time deter you. The stability they provide allows for precision work that simply isn’t possible when you are struggling to keep your footing.

By following the guidelines laid out in this article—checking load ratings, ensuring seam compatibility, and performing regular maintenance—you ensure that your roof jacks for metal roofs serve you well for years to come. Remember, the goal of every roofing project is a watertight home and a safe worker. With the right jacks, you can achieve both.

Other Resources

MBCI – Product category page featuring roof jacks designed for concealed fastener metal roofing systems.

Standing Seam Roof Anchor – Product page describing an adjustable roof jack adapter for standing seam roofs.

ABC Metal Roofing – Product listing detailing roof jacks used with concealed fastener metal panels.

Other Helpful Articles

High-Quality Roof Membrane Replacement – Article outlining key considerations for replacing roof membranes with durable materials.

Roofing Brackets – Guide explaining roofing brackets, their functions, and common applications.

Temporary Roof Scaffolding in London – Article describing temporary roof scaffolding systems used on construction sites in London.