Elk Shingles Secrets: 10 Critical Things to Know

The Ultimate Guide to Elk Shingles History and Care

What Is the Story Behind Elk Shingles

When homeowners and roofing contractors discuss the history of high-quality roofing materials, the conversation almost invariably turns to the legacy of elk shingles. For decades, the Elk Corporation was a dominant force in the roofing industry, renowned for manufacturing some of the most durable and aesthetically pleasing composite shingles on the market. Established in 1955, the company spent over half a century refining its manufacturing processes, eventually creating a brand name that became synonymous with premium quality and innovation.

The reputation of elk shingles was built on their proprietary technology, which included advanced lamination techniques that gave their products a distinct, high-definition look that many competitors struggled to replicate.

The story of elk shingles took a significant turn in the early 21st century. In 2007, the roofing industry witnessed a major consolidation when GAF Materials Corporation, North America’s largest roofing manufacturer, acquired ElkCorp. This acquisition was not merely a financial transaction; it was a merging of two titans of industry. GAF sought to integrate the superior technology and brand loyalty associated with elk shingles into their own extensive product lines.

Following the merger, the two companies initially operated with separate brand identities, but eventually, the product lines were streamlined. This strategic move meant that while the standalone “Elk” brand was gradually phased out, the technology and design philosophy that defined elk shingles lived on within the GAF portfolio, particularly in the Timberline Prestique series.

Understanding what elk shingles represent requires looking beyond just the brand name. They were pioneers in the architectural shingle market. Unlike standard three-tab shingles that lie flat and offer a uniform appearance, elk shingles were designed to mimic the depth and texture of natural wood shakes. This was achieved through a multi-layer construction process that added physical thickness and visual shadow lines to the roof. For many homeowners, installing elk shingles was an investment in curb appeal, as the “High Definition” color blends provided a sophisticated look that enhanced the architectural style of both modern and traditional homes.

The legacy of elk shingles is also tied to their performance claims. They were often marketed with impressive wind warranties and fire resistance ratings, making them a preferred choice in regions prone to severe weather. The WindGuard sealant technology used in elk shingles was engineered to prevent blow-offs during high winds, a common failure point for lesser roofing materials. Although you cannot walk into a supply store and order a new pallet of “Elk” branded products today, the impact of elk shingles on current roofing standards is undeniable, influencing how laminated shingles are manufactured and marketed across the industry.

How to Identify Genuine Elk Shingles

Identifying whether your home currently has elk shingles installed can be a crucial step in maintenance and insurance claims. Since these shingles have been out of direct production as a standalone brand for many years, identifying them requires a keen eye for specific visual characteristics and manufacturing markers.

One of the most telling signs of genuine elk shingles is the distinctive “High Definition” shadow effect. Elk’s manufacturing process used a unique color blending technique that created a sharp contrast between the lighter and darker granules, giving the roof a three-dimensional appearance that was quite advanced for its time.

Another way to verify the presence of elk shingles is to look for the packaging or spare shingles that previous owners might have left behind in the garage or attic. The bundles would clearly display the Elk Corporation logo, often accompanied by product names like “Prestique,” “Capstone,” or “Domain”. If no packaging is available, you might need to inspect the shingles themselves more closely. On some elk shingles, particularly the premium lines, there may be specific manufacturing codes or markings on the underside of the shingle or on the release tape, although these can fade or become illegible over time due to exposure to heat and elements.

The physical dimensions and thickness can also be a clue. Elk shingles, especially the Prestique Plus or similar high-end lines, were marketed as being significantly thicker than standard architectural shingles—sometimes claimed to be up to 50% thicker in their marketing materials of the era. If you compare your roof’s shingles to a standard generic architectural shingle and notice a substantial difference in the laminate thickness, you might be looking at elk shingles. However, be cautious, as many modern high-end shingles also feature increased thickness.

Consulting with a seasoned roofing professional is arguably the most reliable method to identify elk shingles. Roofers who have been in the industry since before 2007 will likely recognize the specific granule cuts and color patterns that were exclusive to Elk. They can differentiate between a GAF Timberline shingle from 2010 and an original elk shingles installation from 2005. This identification is vital because if you need repairs, you must know that you are dealing with a discontinued product, which complicates the process of finding matching materials.

How to Find Replacement Elk Shingles Today

Finding exact replacements for elk shingles in the current market is a significant challenge, akin to finding a needle in a haystack. Because the Elk brand was discontinued following the GAF acquisition, no factories are currently churning out new batches of these specific products. However, “impossible” is a strong word, and there are a few avenues a diligent homeowner can explore if they are determined to find a match for a repair job rather than replacing the entire roof.

The first place to look for replacement elk shingles is in the inventory of long-standing local roofing supply warehouses. Occasionally, distributors may have “bone yards” or old stock corners where discontinued bundles have sat gathering dust. While rare, it is not unheard of for a few bundles of elk shingles to survive in the back of a warehouse. Calling around to local suppliers—specifically those that have been in business for over 20 years—might yield results. You should ask specifically for “old stock Elk Prestique” or similar legacy names.

Another potential source for elk shingles is architectural salvage yards or specialized roofing recyclers. Some companies specialize in harvesting materials from buildings prior to demolition. If a home with a relatively new elk shingles roof is being torn down for redevelopment, these salvagers might reclaim the shingles. However, reusing asphalt shingles is fraught with issues, as the removal process often damages the sealing strips and the fiberglass mat, making them less effective for a second installation.

Online marketplaces and roofing forums can also be a resource. Contractors sometimes list leftover materials from previous jobs on sites like Craigslist, eBay, or specialized roofing forums. You might find a homeowner who had a few bundles of elk shingles left over from a 2006 installation and is now cleaning out their garage. Setting up alerts for terms like “Elk Prestique shingles” or “discontinued Elk roofing” can help you catch these listings as soon as they appear.

If you cannot find the exact branded elk shingles, the next best step is to find the closest visual match. Since GAF absorbed Elk’s technology, the GAF Timberline HD or Ultra HD lines are often the nearest relatives. Bringing a sample of your current shingle to a supplier to compare it against current GAF offerings is a practical “how to find” strategy. While the chemical composition and exact thickness might differ, the color blend might be close enough for a repair on a less visible slope of the roof.

How to Buy the Best Alternatives

Since you cannot simply go out and buy new elk shingles, the “how to buy” process shifts toward purchasing the best possible alternative that respects the legacy and quality of your original roof. The direct successor to the elk shingles lineage is the GAF Timberline series. When shopping for alternatives, you should look for “High Definition” or “HD” labeled shingles, as this terminology was carried over from Elk’s marketing to describe the shadow effect that gives the roof its depth.

When you are ready to buy, it is essential to focus on the specifications that made elk shingles desirable in the first place: weight and warranty. Look for shingles that offer a Class A fire rating and high wind resistance, such as 130 mph wind warranties, which became standard in the premium lines after the GAF-Elk merger. Buying from a “Master Elite” GAF contractor can also be beneficial, as they often have deeper knowledge of the product history and can guide you toward the specific GAF shingle that evolved from the specific line of elk shingles you have, whether it was the Prestique or the Capstone.

Another factor in how to buy alternatives is color matching. Elk shingles had very specific color palettes. Modern GAF colors are similar but not identical. When buying shingles for a patch job, always buy a full bundle and test it on the roof. If the color difference is too stark, you might need to buy enough shingles to replace an entire slope (from ridge to eave) so that the color difference is hidden by the natural break of the roofline. This is often a better investment than having a patch of new shingles that sticks out like a sore thumb against the weathered elk shingles.

For those who loved the thickness of elk shingles, you might want to look at “impact resistant” or “heavyweight” designer shingles. Brands like CertainTeed (Landmark Pro or TL) or Malarkey (Legacy) also offer heavy laminated shingles that rival the old Elk thickness specs. Don’t feel restricted to GAF just because they bought Elk; the goal is to buy a product that matches the quality and look of your old roof.

How Much Do Elk Shingles Costs to Replace

Determining the cost related to elk shingles today is primarily an exercise in estimating replacement costs, as the original product has no current retail price. If you were to look at historical data, elk shingles were considered a premium product, often costing 20-30% more than standard 3-tab shingles of their time. Today, replacing a roof that was originally done in elk shingles involves modern labor and material rates.

For a complete replacement of a roof that currently has elk shingles, you are looking at the price of a premium architectural shingle roof. As of 2026, the cost for removing old layers (tear-off) and installing new high-quality laminated shingles typically ranges from $4.50 to $7.50 per square foot, depending on the complexity of the roof and the region. If your home has 3,000 square feet of roof area, a full replacement could cost between $13,500 and $22,500. This price includes the labor to strip the old elk shingles, repair the decking, and install the new system.

If you are looking at a repair cost rather than a replacement, the price is higher per square foot due to the labor intensity. A contractor might charge $500 to $1,000 for a minor repair involving the replacement of a few damaged elk shingles with a compatible alternative. This cost accounts for the time spent finding a matching shingle, carefully breaking the seal of the surrounding brittle shingles without breaking them, and sealing everything back down.

It is also worth noting the “cost” of warranty claims. If your elk shingles failed due to a manufacturing defect covered under the original warranty (which GAF honors), the financial dynamic changes. GAF may offer a settlement based on the prorated value of the roof. This won’t cover the full cost of a new roof, as it deducts for the years of use you got from the elk shingles, but it can provide a significant credit—sometimes hundreds or thousands of dollars—toward the purchase of new GAF shingles.

How to Install Laminate Shingles Correctly

While you likely won’t be installing new elk shingles, understanding how they were installed—and how their replacements should be installed—is vital for homeowners overseeing a project. The installation of laminated shingles like elk shingles requires a specific nailing pattern to ensure the wind warranty remains valid. Typically, this involves using four to six nails per shingle, placed precisely on the “nail line” or common bond area where the two layers of the laminate shingle overlap.

To install these types of shingles, the roof deck must first be prepared with a proper underlayment, such as felt paper or a synthetic alternative. The starter strip is the most critical component. For elk shingles, a dedicated starter strip was required at the eaves and rakes to seal the first course of shingles down and prevent wind uplift. If you are patching a section, you must ensure the existing starter strip is intact; otherwise, the new shingles will be vulnerable.

Proper alignment is key. Elk shingles usually had a specific exposure, often 5 inches or 5 5/8 inches. When installing replacements, you must match this exposure exactly. If the new shingles have a different dimension, the horizontal lines of the roof will not match up, creating both an aesthetic disaster and a potential leak point where water can travel sideways. Installers must measure the exposure of the existing elk shingles and snap chalk lines to ensure the new courses align perfectly with the old ones.

Sealing is the final step. The thermal sealing strips on elk shingles relied on the sun’s heat to bond. For repairs done in cooler weather, or when integrating new shingles with old ones that have lost their sealant, manual sealing is required. Roofers should apply a dab of asphalt roofing cement (dime-sized) under the tabs of the new shingles to ensure they adhere to the course below. This manual sealing mimics the WindGuard protection that elk shingles were famous for.

How to Clean Your Elk Shingles Roof

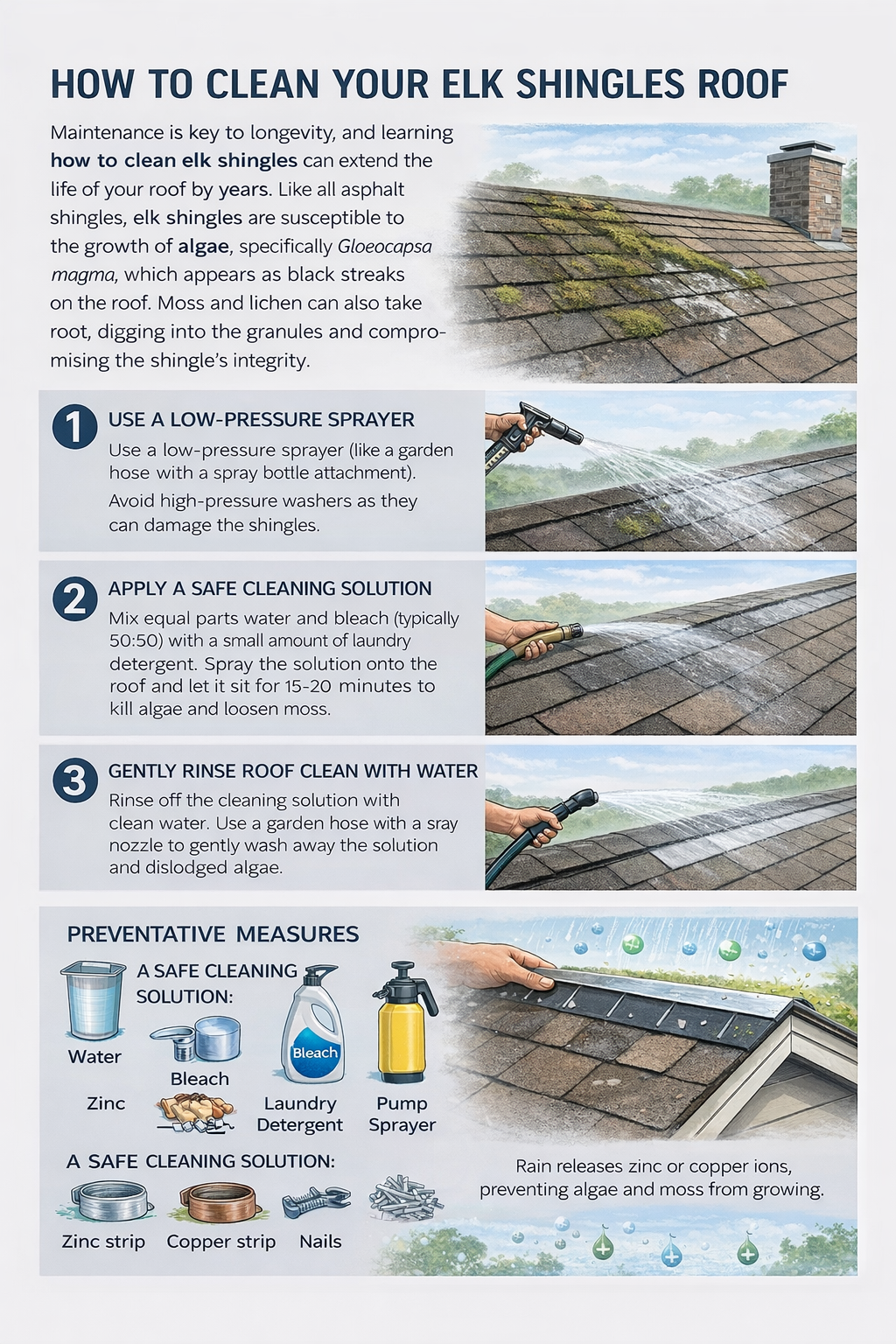

Maintenance is key to longevity, and learning how to clean elk shingles can extend the life of your roof by years. Like all asphalt shingles, elk shingles are susceptible to the growth of algae, specifically Gloeocapsa magma, which appears as black streaks on the roof. Moss and lichen can also take root, digging into the granules and compromising the shingle’s integrity.

To clean elk shingles, you should never use a high-pressure washer. The high velocity of the water can blast away the protective ceramic granules that coat the asphalt core. Once these granules are gone, the UV rays from the sun will rapidly destroy the shingle. Instead, use a “soft wash” method. This involves applying a cleaning solution at low pressure (similar to a garden hose) and letting the chemistry do the work.

A safe and effective cleaning solution for elk shingles is a mixture of water and bleach (typically a 50:50 mix) with a small amount of laundry detergent to help it cling to the surface. Spray this solution onto the roof on a cloudy day to prevent it from evaporating too quickly. Let it sit for 15-20 minutes to kill the algae and loosen the moss. Then, gently rinse it off with clean water. For thick moss growth on elk shingles, you may need to gently brush it with a soft-bristled brush after the chemical treatment has killed it.

Preventative measures are also part of the “how to clean” strategy. Installing zinc or copper strips along the ridge line can prevent future algae growth. As rain hits these metal strips, it releases ions that wash down over the elk shingles, creating an environment where algae and moss cannot survive. This passive cleaning method is highly effective and saves you from having to climb up on the roof repeatedly.

What Is the Cost of Ignoring Roof Maintenance

Ignoring the condition of your elk shingles can lead to costs that far exceed the price of a simple repair. The most immediate cost is water damage. As elk shingles age, they can become brittle and crack. If a leak develops and goes unnoticed, water can rot the roof decking, soak insulation (rendering it useless), and damage drywall and paint inside the home. The cost to repair water damage can easily run into the thousands.

Another hidden cost is energy inefficiency. Elk shingles provide a layer of insulation and reflection. If they are damaged or missing granules, your attic heats up more in the summer, forcing your air conditioner to work harder. This results in higher monthly utility bills. Keeping your elk shingles in good condition ensures they continue to reflect UV rays and protect the thermal envelope of your home.

There is also the cost of decreased property value. A roof with visibly deteriorating elk shingles, covered in moss or missing tabs, is a major red flag for home buyers. It signals deferred maintenance and can force you to lower your asking price or offer credits at closing. Conversely, a well-maintained roof, even one with older elk shingles that are clean and sealed, demonstrates pride of ownership and protects your investment.

Finally, ignoring maintenance can void any remaining warranty coverage. While GAF honors legacy warranties for elk shingles, these warranties often have clauses regarding proper maintenance. If a failure is found to be caused by neglect—such as allowing moss to grow unchecked until it lifts the shingles—the claim will likely be denied. The cost here is the lost opportunity to have the manufacturer pay for your roof replacement.

Advantages and Challenges Connected to Elk Shingles

When evaluating the legacy of elk shingles, it is important to weigh the advantages they offered against the challenges homeowners face today. The primary advantage of elk shingles was their superior durability and aesthetic appeal. They were designed to be thicker and more robust than standard shingles, providing excellent protection against wind and hail. The “High Definition” look remains a selling point, as these roofs often retain their visual depth even after two decades of exposure.

Another advantage is the transferability of the warranty in some cases. GAF’s decision to honor elk shingles warranties means that homeowners are not left high and dry. This corporate backing provides peace of mind that is rare when a product line is discontinued. The integration with GAF also means that technical support and documentation for elk shingles are still accessible through GAF’s archives, which is helpful for inspections and real estate transactions.

However, the challenges are significant. The primary challenge connected to elk shingles is the difficulty of repair due to discontinuation. As mentioned, finding an exact color match is nearly impossible. This can lead to “Frankenstein roofs” with mismatched patches that detract from curb appeal. Homeowners often face the difficult decision of replacing a mostly good roof just because a few elk shingles are missing and cannot be matched.

Another challenge is the confusion regarding warranty claims. While GAF honors the warranties, the process can be bureaucratic. Proving that a failure is a manufacturing defect inherent to the elk shingles rather than normal wear and tear requires documentation and sometimes professional inspections. Additionally, navigating the merger details to understand which specific policy applies to a roof installed in the transition year of 2007 can be complex for the average homeowner.

Critical Tech Specs: Elk Roofing Shingles Explained

To fully understand the product on your roof, one must dive into the technical details of elk roofing shingles. These were not just standard asphalt slabs; they were engineered systems. A key point of confusion for many is the relationship between the brands, specifically gaf elk shingles. After the 2007 merger, products were temporarily co-branded as “GAF-Elk,” combining the marketing power of both entities. This means if you see packaging with both names, you have a product from that transition era, possessing the tech of Elk with the backing of GAF.

A common question homeowners ask is: are elk shingles still available? The short answer is no, not as a distinct manufacturing run. You cannot order them from a factory. However, their DNA persists in GAF’s Timberline HDZ and Ultra HDZ lines. If you need to verify what you have, you might wonder how thick are elk timberline shingles.

The legacy Elk Prestique and Timberline Prestique High Definition shingles were marketed as being up to 32% thicker than standard architectural shingles of their time, with some marketing claims stating the laminated layers created a 1/2-inch profile for the “ultra” heavy versions. This physical thickness was a primary selling point, contributing to their high impact resistance and the deep shadow lines that defined their aesthetic.

FAQ : Elk shingles

1. Can I still file a warranty claim for my old elk shingles?

Yes, GAF honors legacy warranties for elk shingles that are still within their coverage period. You will need to provide proof of purchase and installation date to initiate a claim through GAF’s warranty department.

2. What is the best modern shingle to match my existing elk shingles?

The GAF Timberline HDZ or Ultra HDZ shingles are the direct successors and offer the closest visual match in terms of “High Definition” color blends and shadow effects, although an exact color match is not guaranteed.

3. How do I know if my shingles are Elk or GAF?

Check for the “Elk” logo on any spare packaging, or look for specific brand markings on the underside of the shingles. If the roof was installed before 2007, they are likely Elk; if installed between 2007 and 2011, they may be co-branded as GAF-Elk.

4. Are elk shingles asbestos-free?

Yes, elk shingles manufactured in the modern era (post-1980s) are fiberglass-based asphalt shingles and do not contain asbestos. They are safe to handle and dispose of using standard construction waste protocols.

5. Why were elk shingles considered superior?

Elk shingles were marketed as being thicker, having better wind resistance (WindGuard technology), and featuring a more distinct, aesthetic wood-shake look compared to the flat, standard shingles of their competitors.

Conclusion and Final Thoughts

In the world of residential roofing, elk shingles stand as a testament to quality manufacturing and innovative design. Although the company itself has been absorbed into the larger entity of GAF, the roofs they covered continue to protect hundreds of thousands of homes across North America. For homeowners who currently have elk shingles on their property, the key is proactive maintenance and informed decision-making.

Understanding the history of the acquisition helps in navigating warranty claims and finding suitable replacements. While you may never be able to buy a brand-new bundle of elk shingles again, knowing that their technology lives on in the GAF Timberline series provides a clear path for repairs and eventual replacement. The durability that made elk shingles famous means that many of these roofs are still performing well, years past their expected service life.

Ultimately, whether you are looking to clean, repair, or replace your elk shingles, the advice remains the same: treat the roof with care, consult with professionals who understand the legacy of the brand, and value the protection it provides. The story of elk shingles is one of industry evolution, reminding us that quality materials leave a lasting impact long after the brand name has changed.

Other Resources

GAF Roofing – Technical brochure providing specifications and installation details for Timberline HD asphalt shingles.

ELK Roofing – Informational article discussing the most popular asphalt shingle styles and their characteristics.

ARoofing – Resource page referencing ELK Corporation premium roofing and building products.

Other Helpful Articles

Roofing Brackets – Article explaining roofing brackets, their uses, and installation considerations.

Temporary Roof Scaffolding in London – Guide describing temporary roof scaffolding systems used on construction projects in London.

Roof Jacks for Metal Roofs –