Flat Roof Vents Guide: Essential Tips for a Safer Home

Flat Roof Vents Explained: Secrets to Stop Leaks Fast

Proper ventilation is the silent guardian of any roofing system, yet it is frequently misunderstood by homeowners and builders alike. When dealing with flat roofing systems, the margin for error is significantly smaller than with pitched roofs. Flat roof vents are not just accessories; they are critical components that ensure the longevity of the entire building structure. Without functioning flat roof vents, moisture gets trapped, leading to rotting decks, ineffective insulation, and dangerous mold growth. This comprehensive guide will explore every aspect of flat roof vents, from identification and purchase to installation and maintenance, ensuring you have the knowledge to protect your investment.

What Is a Flat Roof Vent?

A flat roof vent is a specialized device designed to allow air to circulate beneath the waterproof membrane of a flat roof. Unlike pitched roofs, which rely on natural convection to push hot air out of ridge vents, flat roofs require specific engineering to move air effectively. Flat roof vents typically consist of a base, a riser (or throat), and a cap (often called a mushroom or hood) that prevents rain and snow from entering the building while allowing stale air and moisture vapor to escape.

These devices are essential because the space between the ceiling and the roof deck—often called the plenum or void—can become a trap for warm, moist air rising from the living space below. If this moisture hits a cold roof deck, it condenses into liquid water. Flat roof vents provide the escape route for this moisture. They come in various materials, including durable aluminum, galvanized steel, and high-impact plastics, each designed to withstand the harsh conditions of direct sun exposure and standing water common on flat roofs.

Understanding what constitutes a high-quality vent is the first step in roof maintenance. Premium flat roof vents feature insect screens to keep pests out and wide flanges that allow for a watertight seal with the roofing membrane, whether it is EPDM, TPO, or modified bitumen.

Do Flat Roofs Need to Be Vented?

One of the most common questions in the roofing industry is whether flat roof vents are strictly necessary. The answer depends largely on the type of roof construction: “cold roof” versus “warm roof.”

In a cold roof assembly, insulation is placed between the joists, leaving an empty space (void) above the insulation but below the roof deck. Here, flat roof vents are absolutely mandatory. Without them, the warm air leaking from the house will condense on the underside of the cold roof deck during winter, leading to “roof sweating,” rot, and structural failure. Building codes often require a specific ratio of ventilation area to roof area to ensure this moisture is evacuated.

Conversely, in a warm roof design, the insulation is placed on top of the roof deck. This keeps the deck warm and prevents condensation from forming on its surface. In this specific scenario, flat roof vents for the roof structure itself may not be needed, as the entire assembly is sealed. However, even on warm roofs, flat roof vents are often still required for other purposes, such as exhausting bathroom fans, kitchen hoods, or dryer lines. Therefore, while the structural need varies, the functional need for flat roof vents to service the building’s interior remains constant.

Types of Ventilation Systems for Flat Roofs

When selecting flat roof vents, it is crucial to understand that different systems serve different physical needs. The market offers several distinct categories of flat roof vents designed for specific airflow dynamics.

Passive Ventilation Systems:

Most flat roof vents are passive, meaning they have no moving parts. “Breather vents” or “pop vents” are the most common examples. These rely on the stack effect—where warm air naturally rises—and external wind pressure to pull air out of the roof void. For these flat roof vents to work, there must be an intake source, often provided by soffit vents at the roof’s edge, creating a continuous current of air.

Active or Mechanical Systems:

In areas with high humidity or complex roof geometries where natural airflow is insufficient, mechanical flat roof vents are used. These may be solar-powered fans or hardwired electric turbines that actively suck moisture out of the cavity. While more expensive, these flat roof vents guarantee air movement regardless of the weather conditions.

Specialty Exhaust Systems:

Not all flat roof vents ventilate the roof deck; some ventilate the living space. This includes the “plumbing jack” (venting sewer gases) and dedicated exhaust ports for HVAC systems. Distinguishing between a breather vent (for the roof) and an exhaust vent (for the house) is vital, as connecting a bathroom fan to a breather vent can pump moisture directly into your roof structure, causing catastrophic damage.

Flat Roof Vertical Dryer Vent Cover Explained

A specific and critical sub-category of flat roof vents is the vertical dryer vent cover. Venting a clothes dryer through a flat roof presents unique challenges because dryers push hot, lint-filled air that can easily clog standard screens, creating a fire hazard.

A specialized flat roof vertical dryer vent cover, such as the “gooseneck” style or high-clearance curb model (like the DryerJack 486), is designed with a damper that opens only when the dryer is running. Unlike standard flat roof vents, these must not have a screen, as screens trap lint. Instead, they rely on a heavy, gravity-assisted damper or a floating shuttle to keep pests out when the dryer is off.

These flat roof vents must be installed on a raised curb or have a tall riser to stay above the snow line and standing water. If a standard low-profile vent is used for a dryer, it will likely become submerged during heavy rain or buried in snow, blocking the exhaust and potentially causing the dryer to overheat or the moist air to back up into the home. Investing in high-quality vertical flat roof vents for dryers is a safety necessity, not just a building requirement.

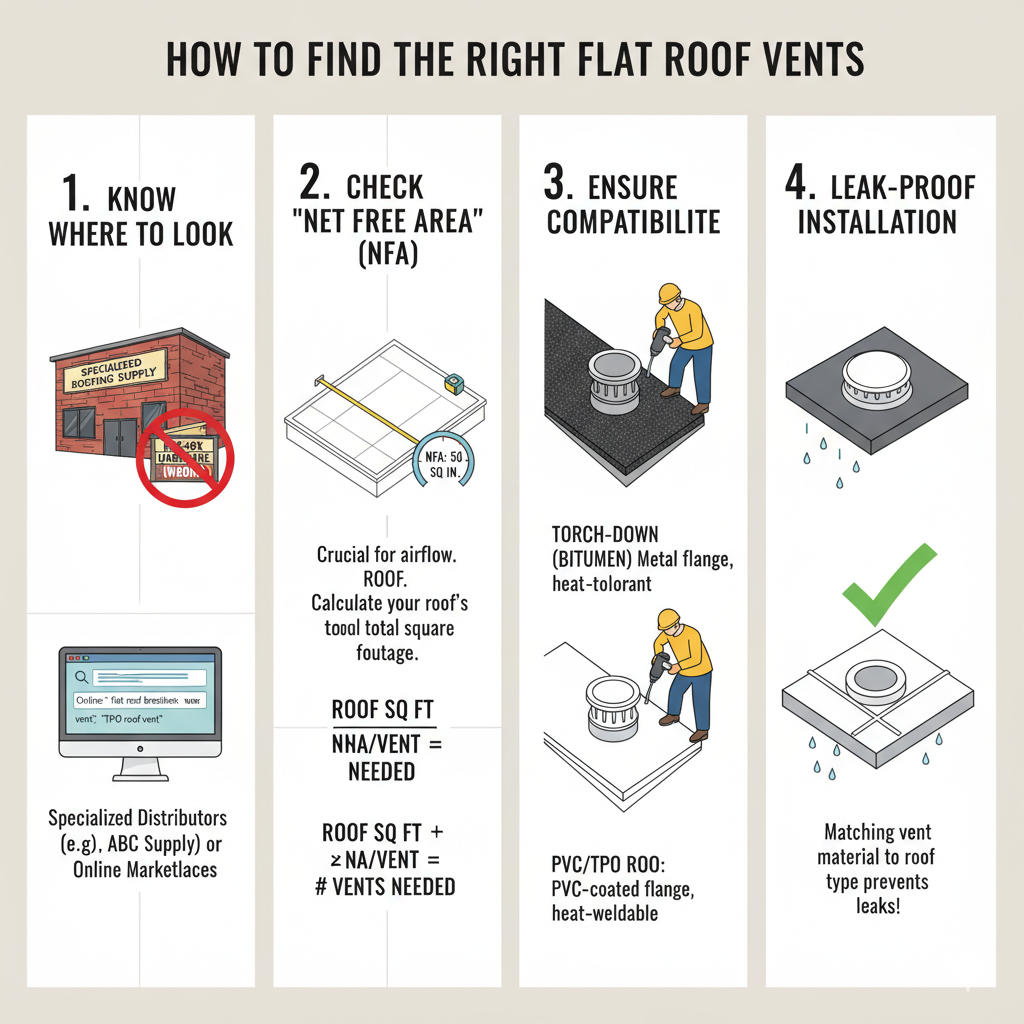

How to Find the Right Flat Roof Vents

Finding the correct flat roof vents requires knowing where to look and what specifications to verify. You typically cannot find professional-grade flat roof vents at a generic big-box hardware store; those outlets usually stock vents for shingle roofs (sloped roofs) which are incompatible with flat systems.

To find the best flat roof vents, you should visit specialized roofing supply distributors (like ABC Supply or Beacon Building Products in the US, or specialized merchants in the UK). Online marketplaces also offer them, but you must search for terms like “flat roof breather vent” or “TPO roof vent.” When browsing, look for the “Net Free Area” (NFA) rating. This number tells you how much airflow the flat roof vents provide. You will need to calculate your roof’s total square footage to determine how many vents you need based on their NFA rating.

Additionally, compatibility is key. If you have a torch-down (bitumen) roof, you need flat roof vents with a metal flange that can take heat. If you have a PVC or TPO roof, you need flat roof vents with a PVC-coated flange that can be heat-welded directly to the membrane. finding the right material match ensures a leak-proof installation.

How to Buy Flat Roof Vents: A Buyer’s Guide

Once you have located a supplier, the process of buying flat roof vents involves checking for durability and completeness. Never buy used flat roof vents; the flange is often warped during removal, making a watertight seal impossible.

Checklist for Buying:

-

Material Thickness: Look for heavy-gauge aluminum (0.025 inches or thicker) or spun copper. Thin aluminum flat roof vents can dent during hail storms, leading to pooled water.

-

Collar Height: Ensure the vent rises at least 4 to 8 inches above the roof deck. Buying flat roof vents that sit too low is a recipe for leaks during flash floods or snow accumulation.

-

Cap Design: Buy flat roof vents with a removable cap. This feature allows you to clean the throat of the vent without ripping the entire unit off the roof later.

-

Flashing Width: The flange (the flat part that sits on the roof) should be at least 4 inches wide on all sides. This gives you ample room to adhere your roofing membrane over the flat roof vents.

When you are ready to buy, purchase 10% more flat roof vents than your calculations suggest if you have a complex roof layout, as you may need to place them closer together in corners where air pockets form.

How Much Do Flat Roof Vents Cost?

The cost of flat roof vents varies significantly based on the material and the complexity of the installation. For a standard passive aluminum breather vent, prices in 2026 typically range from $75 to $150 per unit for the material alone. High-end copper or stainless steel flat roof vents can cost between $200 and $300 each.

However, the material is the smaller part of the equation. The labor to install flat roof vents is where the bulk of the cost lies. Professional roofers often charge a minimum call-out fee or a day rate, which can range from $400 to $800 per day depending on your location.

Estimated Project Costs:

-

Single Vent Replacement: If you are hiring a pro to replace just one or two flat roof vents, expect to pay between $450 and $750 total. The high cost is due to the setup time and the need to patch the roofing membrane precisely.

-

New Installation (Retrofit): Cutting new holes into an existing roof to add flat roof vents is more labor-intensive. This involves structural cutting, insulation repair, and flashing. Expect $600+ per vent.

-

New Construction: When installed during a full roof replacement, the cost per vent drops significantly, often to $100-$200 per unit (labor and materials) since the crew is already on-site and the deck is accessible.

Budgeting for quality flat roof vents is always cheaper than repairing the water damage caused by condensation.

How to Vent a Flat Roof: Design Principles

Learning how to vent a flat roof involves understanding the physics of airflow. You cannot simply place flat roof vents randomly and hope for the best. The goal is to create a cross-flow of air that sweeps the entire underside of the roof deck.

The 1:150 Rule:

A common building code standard is the 1:150 rule, which states that for every 150 square feet of attic space, you need 1 square foot of Net Free Area (NFA) of ventilation. This area should be split 50/50 between intake (soffit) and exhaust (roof) vents.

Placement Strategy:

To effectively use flat roof vents, place them at the highest points of the roof if there is any slope at all (even flat roofs usually have a 1/4 inch per foot pitch). Hot air rises to the highest point. You should space flat roof vents evenly across the roof surface to avoid “dead zones” where air stagnates. A good rule of thumb is one vent for every 40-50 square meters of roof area, though this varies by local code.

The Intake Problem:

The biggest challenge with flat roofs is often the lack of overhangs for intake vents. If your roof has parapet walls, you may need to install wall louvers or “fascia vents” to serve as the air intake. Without intake air entering the system, your flat roof vents will act like a straw with a capped end—no air will move, rendering the vents useless.

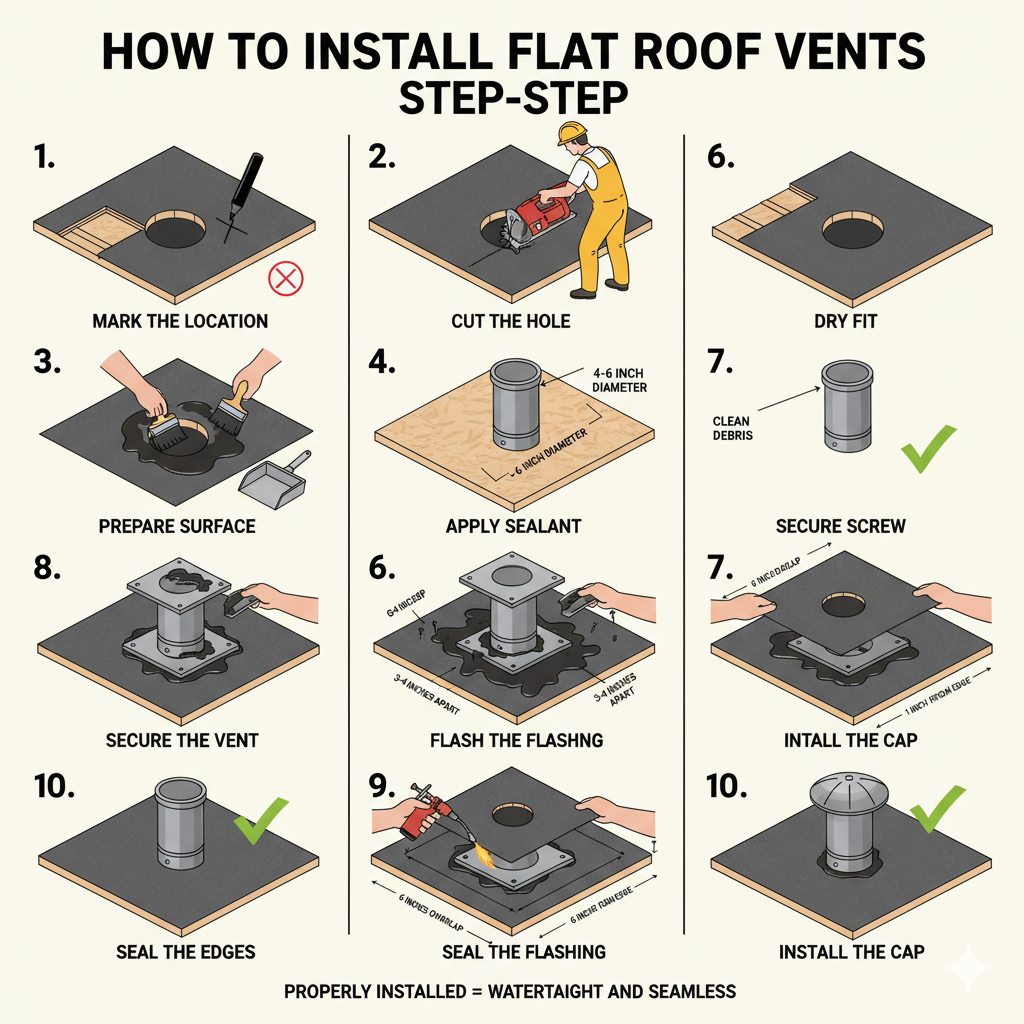

How to Install Flat Roof Vents Step-by-Step

Installing flat roof vents requires precision to ensure the roof remains watertight. Below is a detailed procedure for installing a standard flange-mounted breather vent on a modified bitumen or rolled roofing system.

-

Mark the Location: Identify where the flat roof vents should go. Ensure you are between joists so you do not cut into structural beams.

-

Cut the Hole: Using a reciprocating saw, cut a hole through the roofing membrane and the deck (plywood/OSB) that matches the diameter of the vent stack (usually 4 to 6 inches).

-

Prepare the Surface: Clean the area around the hole thoroughly. Remove loose granules or debris. If the roof is old, apply a bitumen primer to the membrane where the flange will sit.

-

Dry Fit: Place the flat roof vents into the hole to ensure they fit snugly.

-

Apply Sealant: Lift the vent and apply a thick bed of roofing cement (mastic) to the underside of the flange. Do not be shy with the mastic; this is your primary seal.

-

Secure the Vent: Press the vent down into the mastic. Screw the flange to the roof deck using galvanized roofing screws or nails. Place screws about 1 inch from the edge of the flange, spaced 3-4 inches apart.

-

Flash the Flange: This is the most critical step. Cut a piece of matching roofing membrane (cap sheet) that extends at least 6 inches past the flange on all sides. Cut a hole in the center for the vent stack.

-

Seal the Flashing: Apply roofing cement over the top of the metal flange and the surrounding roof. Embed the new membrane patch over the flange. If using torch-down, use a torch to fuse the patch to the existing roof and the primed metal flange.

-

Seal the Edges: Apply a final bead of sealant around the stack where the membrane meets the metal rising up, and around the outer edges of the patch.

-

Install the Cap: Secure the hood or cap onto the vent stack to prevent rain entry.

Properly installed flat roof vents should look like a seamless bump in the roof, fully integrated with the surrounding material.

How to Clean and Maintain Your Vents

Even the best flat roof vents require maintenance to function correctly. Debris, bird nests, and dust can clog the screens, stopping airflow completely.

Cleaning Process:

Start by safely accessing the roof. Inspect the flat roof vents for physical damage. If the cap is removable, unscrew or unclip it. Use a stiff brush to scrub the insect screen. If lint or dust is caked on, a shop vacuum is highly effective for sucking out the blockage.

Frequency:

You should clean flat roof vents at least twice a year—once in late autumn (to clear fallen leaves) and once in spring (to clear winter debris and check for ice damage).

Rust and Sealant Checks:

While cleaning, inspect the base of the flat roof vents. Look for cracked sealant or rusting metal. If the mastic around the flange looks dried out or cracked, apply a fresh layer of roof sealant immediately. This proactive step prevents the most common cause of leaks related to flat roof vents. If you find a vent that is heavily rusted or crushed, do not try to repair it; replacing flat roof vents is safer and often easier than patching a failing unit.

Advantages and Challenges Connected to Flat Roof Vents

Implementing a robust system of flat roof vents brings significant benefits but also introduces specific challenges that building owners must manage.

Advantages:

The primary advantage of flat roof vents is the prevention of condensation. By keeping the roof insulation dry, the R-value (insulating power) is maintained, which keeps energy bills lower. Dry insulation also prevents the wood deck from rotting, extending the structural life of the building by decades. Furthermore, properly functioning flat roof vents reduce the thermal shock on the roof membrane by helping to moderate the temperature difference between the inside and outside, preventing the membrane from blistering or cracking prematurely.

Challenges:

The main challenge is that every vent is a penetration in the roof—a potential leak point. If flat roof vents are installed poorly, water will enter exactly where you cut the hole. Another challenge is snow accumulation. On a flat roof, snow does not slide off. If the flat roof vents are too short, they can be buried, stopping airflow when it is needed most to prevent ice dams. Finally, in urban areas, flat roof vents can become entry points for pests if the screens are compromised, requiring vigilant maintenance.

Despite these challenges, the consensus among roofing professionals is clear: the risks of not having flat roof vents (rot, mold, structural failure) far outweigh the maintenance requirements of having them.

FAQ : Flat roof vents

How many flat roof vents do I need for a 1000 sq ft roof?

Following the 1:150 rule, you need roughly 7 square feet of ventilation. If using standard flat roof vents with 50 sq inches of NFA each, you would need approximately 10 vents to ensure adequate airflow.

Can I install flat roof vents myself?

While possible for a skilled DIYer, installing flat roof vents involves cutting through the waterproof membrane. One mistake can lead to major leaks. It is highly recommended to hire a professional roofer who understands flashing techniques.

Do flat roof vents leak during heavy rain?

Quality flat roof vents are designed with internal baffles and overhangs to prevent water entry. However, if the flashing around the base fails or if the water level on the roof rises above the vent curb (flooding), they can leak.

What is the best material for flat roof vents?

Aluminum is the industry standard because it is lightweight and rust-resistant. However, for coastal areas with salt air, heavy-duty plastic or stainless steel flat roofing vents are superior options to prevent corrosion.

Can I use a ridge vent on a flat roof?

No, ridge vents are designed for the peak of a sloped roof. They cannot function on a flat surface. You must use dedicated flat roofing vents like mushroom vents, box vents, or pop vents designed for zero-slope applications.

Conclusion

In the world of home maintenance, flat roof vents are often unsung heroes. They perform the dirty work of expelling stale air and moisture, protecting the structural integrity of your property day and night. From understanding the difference between cold and warm roof setups to selecting the right vertical dryer vent cover, every detail matters. By investing in high-quality flat roofing vents and adhering to a strict schedule of inspection and cleaning, you ensure that your roof remains not just a cover, but a durable shield for your home. Whether you are building new or retrofitting an older property, remember that proper ventilation is never an expense—it is an investment in the longevity and safety of your building.

Other Resources

FAMCO – Manufacturer product page listing roof vents designed for residential and commercial roofing systems.

RoofVents – Informational page explaining flat roof ventilation options and airflow considerations.

Monarch Roofing – Educational article discussing flat roof vent types and their functions.

Other Helpful Articles

Roof Vent Cap Installation – Guide explaining steps and considerations for installing roof vent caps.

Metal Roof Ridge Vent – Article detailing ridge vent systems designed for metal roofs.

Roof Vent Installation – Article outlining general roof vent installation methods and best practices.

Roof Ridge Vent – Overview of roof ridge vents and their role in proper attic ventilation.